Unleashing Innovation with Rapid Prototype Injection Molding by Deep Mould: The Future of Metal Fabrication

Understanding Rapid Prototype Injection Molding: The Key to Accelerated Product Development

In today's highly competitive manufacturing landscape, speed, efficiency, and precision are paramount. Rapid prototype injection molding emerges as a revolutionary process that combines traditional injection molding techniques with rapid prototyping methods. This cutting-edge technology enables metal fabricators and product designers to quickly produce high-fidelity prototypes that closely replicate final production parts. At Deep Mould, we specialize in leveraging this innovative process to help clients achieve faster time-to-market, reduced costs, and superior quality in their manufacturing projects.

The Evolution of Prototype Manufacturing: From Concept to Reality

Historically, creating prototypes was a long, costly, and complex process that involved manual craftsmanship or limited 3D printing options. Traditional injection molding, while effective for mass production, was often too slow and expensive for initial prototype stages. The advent of rapid prototype injection molding bridged this gap, offering a cost-effective, quick, and accurate means to develop prototypes suitable for testing, validation, and iterative design improvements. This transformation has empowered metal fabricators at Deep Mould to deliver bespoke, high-quality prototypes with remarkable speed, enabling businesses to refine their products efficiently before committing to full-scale production.

Why Choose Rapid Prototype Injection Molding? Key Benefits for Metal Fabricators

- Significantly Reduced Lead Times: Traditional methods can take weeks or months; rapid methods can cut this down to days, enabling quicker feedback and adjustments.

- Cost-Efficiency: Lower tooling costs make it feasible to develop prototypes in small batches without sacrificing quality, ideal for testing and marketing campaigns.

- High Fidelity and Accuracy: Produces prototypes that closely resemble finished parts, including complex geometries, fine details, and precise dimensions.

- Design Flexibility: Allows rapid iteration of prototypes, facilitating innovative design modifications without significant delays or costs.

- Material Versatility: Supports a wide array of materials, including metals, plastics, and composites, tailoring prototypes to specific application needs.

The Process of Rapid Prototype Injection Molding at Deep Mould

Step 1: Concept Design and CAD Modeling

The journey begins with a detailed computer-aided design (CAD) model. Our engineers collaborate closely with clients to optimize designs for manufacturability, ensuring that the prototype accurately reflects the intended final product. We leverage advanced CAD software to prepare models suitable for rapid tooling.

Step 2: Rapid Tooling Fabrication

Using innovative techniques such as CNC machining, 3D printing, or soft tooling, we quickly produce a functional mold. This stage is pivotal in achieving substantial time reductions compared to traditional steel tooling. The choice of materials and methods depends on the prototype specifications, budget, and expected production volume.

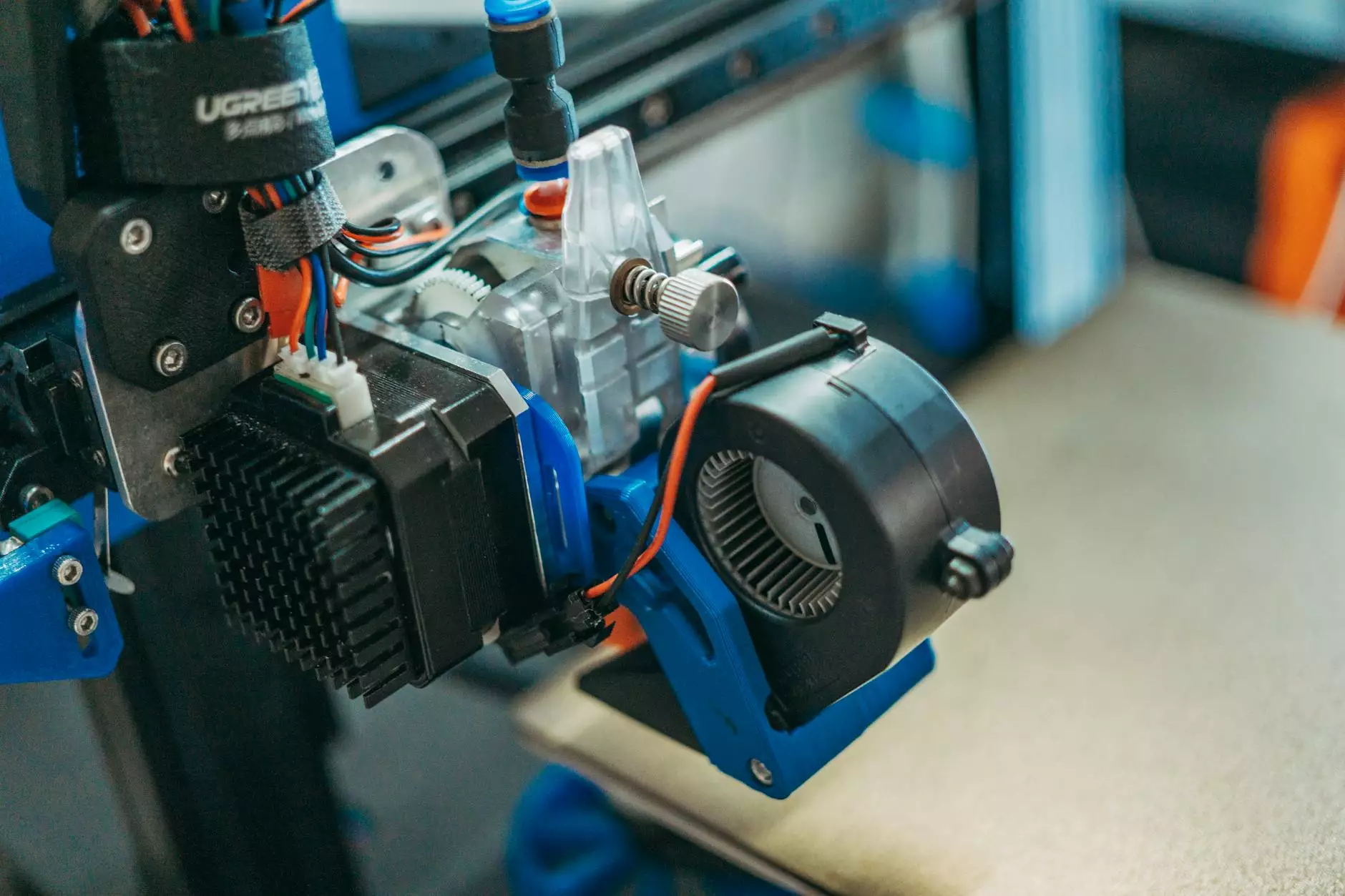

Step 3: Injection Molding of Metal or Plastic Components

Once the mold is ready, we proceed with the injection molding process, where high-quality metals or plastics are injected into the mold cavity under controlled pressure and temperature conditions. The result is a highly precise prototype with intricate details and consistent features.

Step 4: Post-Processing and Quality Control

After molding, prototypes undergo meticulous finishing processes, such as polishing, machining, or coating, to enhance surface quality. Rigorous inspection and testing ensure that the prototype meets strict dimensional and functional specifications, providing invaluable insights for product development.

Step 5: Iterative Refinement and Final Validation

Clients receive the prototypes for evaluation, testing, and feedback. This cycle facilitates rapid iterations, making design modifications cost-effectively. Once finalized, the same process can be scaled for mass production using durable tooling and materials.

Applications of Rapid Prototype Injection Molding in Metal Fabrication

This versatile process finds its utility across various industries and applications, including:

- Automotive: Rapid manufacture of complex metal components for testing and validation before production.

- Aerospace: Prototype parts that require high precision and strict tolerances for safety and performance testing.

- Medical Devices: Custom metal parts with intricate features for prototypes, enabling thorough testing and certification.

- Consumer Electronics: Metal housings and components for ergonomic and aesthetic assessments.

- Industrial Equipment: Durable prototypes that mimic final metal parts used in machinery and tools.

Why Deep Mould Is Your Premier Partner in Rapid Prototype Injection Molding

At Deep Mould, we combine decades of expertise in metal fabrication with cutting-edge technology to deliver unmatched rapid prototype injection molding services. Our dedicated team of engineers, designers, and technicians work collaboratively to ensure every prototype aligns perfectly with your specifications, budget, and timeline. Key advantages include:

- Advanced Technology Infrastructure: State-of-the-art CNC machines, 3D printers, and injection molding equipment ensure precision and speed.

- Custom Solutions: Tailored prototyping processes designed to suit the unique needs of each project and industry.

- Expert Consultation: Guidance on design optimization and material selection for optimal prototype performance.

- Comprehensive Quality Assurance: Rigorous testing and inspection protocols guarantee high standards of quality and reliability.

- Cost-Effective and Environmentally Conscious: Efficient workflows reduce waste and energy consumption, aligning with sustainable manufacturing practices.

Partnering with Deep Mould means gaining access to a powerhouse of innovation, efficiency, and quality — transforming your conceptual ideas into tangible prototypes faster and more accurately than ever before.

The Future of Metal Fabrication with Rapid Prototype Injection Molding

As technology advances, rapid prototype injection molding is poised to become even more integral to metal fabricators and manufacturers worldwide. Innovations such as multi-material molding, bio-based resins, and integrated digital workflows are expanding possibilities, allowing for faster, more sustainable, and more sophisticated prototypes. Companies like Deep Mould are at the forefront of these trends, continuously investing in new methods to enhance speed, quality, and cost-efficiency.

Moreover, the integration of Automation and Artificial Intelligence in the design and manufacturing process is expected to reduce human error further and optimize production cycles. This synergy of technology and expertise will redefine how industries approach product development, emphasizing agility, precision, and eco-friendliness.

Maximize Your Product Development Potential with Deep Mould

Choosing the right partner for rapid prototype injection molding can significantly impact your project's success. Deep Mould’s commitment to quality, innovation, and customer satisfaction positions us as a leader in this transformative space. Whether you are developing a new product, testing innovative designs, or preparing for final production, our rapid prototyping solutions will enable you to:

- Reduce Time-to-Market: Accelerate your development cycle to beat competitors.

- Lower Costs: Minimize upfront investment with cost-effective tooling and manufacturing solutions.

- Enhance Product Quality: Produce high-fidelity prototypes for testing, validation, and presentation purposes.

- Facilitate Iterative Design: Rapidly test and refine concepts, reducing risk and improving overall design quality.

- Streamline Your Workflow: Achieve seamless integration from concept to final prototype and beyond.

Investing in rapid prototype injection molding with Deep Mould means opening doors to innovation, efficiency, and success in your product development journey.

Contact Deep Mould Today to Accelerate Your Metal Fabrication Projects

Ready to embrace the future of metal fabrication with rapid prototype injection molding? Connect with our team at Deep Mould to discuss your project requirements, explore custom solutions, and discover how our expertise can help you stay ahead in the competitive manufacturing arena. Our commitment to excellence and innovation makes us the trusted partner for businesses seeking superior prototypes and metal components.